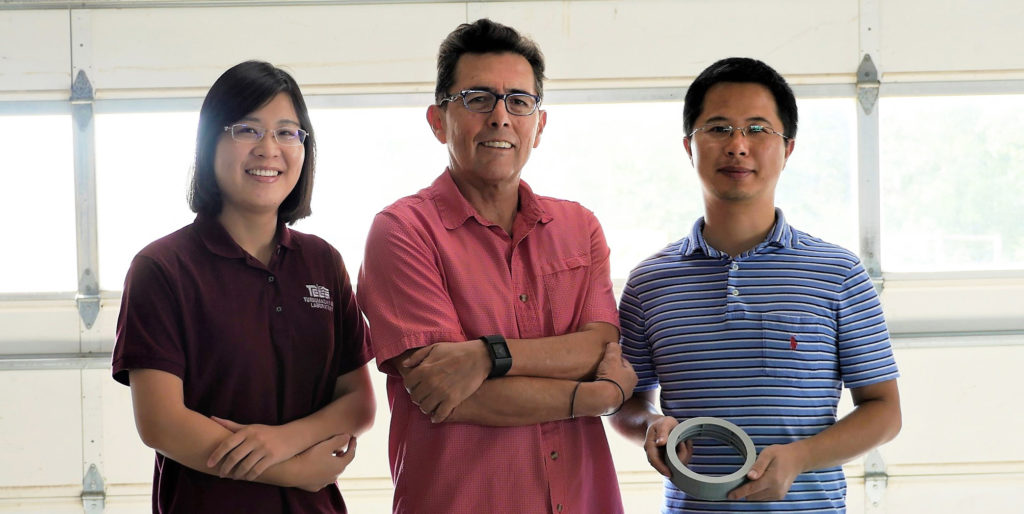

Left to right: Dr. Jing Yang, Dr. Luis San Andrés and Xueliang Lu

Turbo Lab seal update increases damping effectiveness

A Turbomachinery Laboratory invention is getting a new twist

The pocket damper seal was created at the Turbo Lab as an alternative to the labyrinth seal. The Turbomachinery Research Consortium (TRC), an organization of turbomachinery manufacturers and end users supporting research projects at the Turbo Lab, funded the testing of the original pocket damper seal as well as improvements made over time.

Seals are used to reduce leakage from high pressure zones to low pressure zones in compressors and turbines. The labyrinth seal has a number of cavities made by sharp teeth, on the stator or the rotor or both, where a gas loses energy after passing through a tight clearance. Pocket damper seals have added restraints in the cavities of the labyrinth seal, making them more effective to reduce the circumferential swirl velocity development and also offering substantial gains in damping needed to ameliorate rotor vibrations. The new pocket damper seal will include a small change that will further increase its damping effectiveness. Graduate student Xueliang Lu and research associate Dr. Jing Yang, along with Dr. Luis San Andrés, Mast-Childs Chair Professor in the Department of Mechanical Engineering, are responsible for the invention, already tested in the laboratory.

San Andrés said the pocket damper seal has been a success since invented in the early 1990s. The original pocket damper seal was licensed to many companies and is still much in use in industry. He is confident that the improvement to the seal will increase the use and sales of the invention.

“I am excited to have the opportunity to introduce it. The innovation will be great for our Turbomachinery Research Consortium members,” said Dr. San Andrés. “They’ll have the first look, and opportunity to use it.”

The team is awaiting a provisional patent for the seal.

The Texas A&M Engineering Experiment Station (TEES) Turbomachinery Laboratory makes a vital impact on turbomachinery and related industries through research, education and professional workforce development.

I am excited to have the opportunity to introduce it. The innovation will be great for our Turbomachinery Research Consortium members.

Dr. San Andrés