As part of the Texas A&M Turbomachinery Laboratory , the R&P Group focuses on conducting fundamental and applied research to advance the state of the art of rotating equipment. The Group’s research projects span a wide variety of topics tailored to address different technical needs. From multi-year research development of new concepts to fast-paced short-term projects, we provide technical contributions to advance low TRL concepts and more immediate and practical solutions to our sponsors.

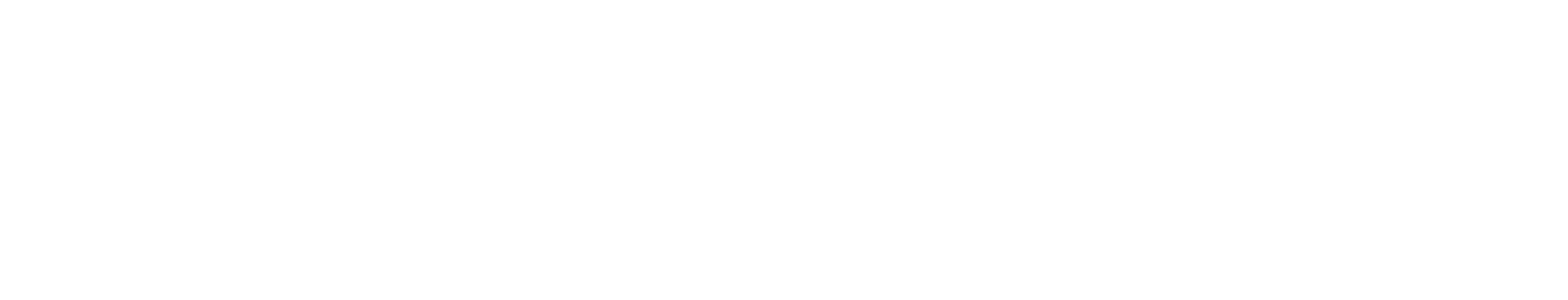

Static and Dynamic Performance of Radial Gas Foil Bearings

Unique test facility to measure the static and dynamic load performance of gas (oil-free) bearings for advanced turbochargers, micro turbines and fuel cells as applied to microturbomachinery.

The test rig design allows the easy installation and dismantling of test bearings, 35 mm OD. The rig consists of a ball-bearing T25 turbocharger modified by replacing the compressor wheel with a test bearing section. The maximum shaft speed is 75 krpm (cold air supply).

Two 100 N (20 lbf) electromagnetic shakers apply dynamic load excitations to 600 Hz on the bearing and an ad-hoc mechanism applies static loads on the test bearing mounted atop a precise positioning electronic system.

The instrumentation includes eddy current sensors, load cells and accelerometers to delver the test system frequency response and identification of force coefficients over a frequency range.

Facility used to measure (for the first time) the force coefficients of metal mesh foil bearings, shimmer bump-type foil bearings, as well as to quantify the effect of coatings on foil bearing performance.

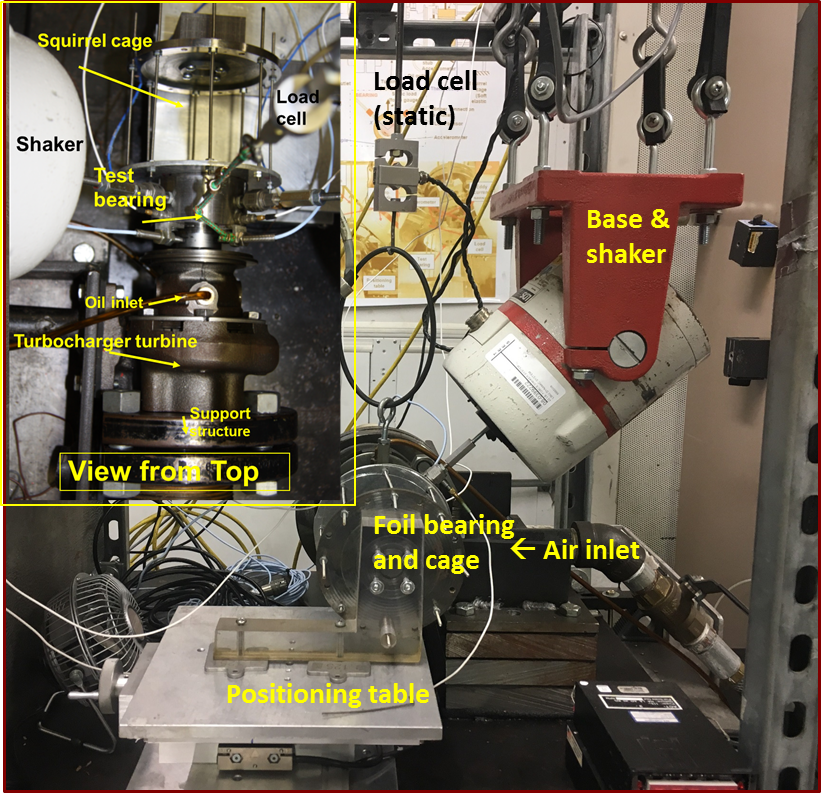

Test rig for static and dynamic performance of thrust gas foil bearings

To measure the static and dynamic performance of oil-free turbochargers, micro turbines and fuel cells. The test rig con

sists of a solid steel thrust collar spun by a 2.2 kW router motor (40 krpm max), a rotor collar (101 mm OD), and a test bearing attached to a thrust load shaft. An aerostatic plenum contains two porous carbon bushings on which the load shaft floats, and when pressurized, pushes on the shaft to produce a load on the test bearing (580 N max). A torquemeter and shaker attach on one end of the load shaft. The shaker delives dynamic loads (max. 100 N) to excite the test bearing axial displacements. Axial stiffness and damping coefficients are extracted from force/displacement frequency response functions obtained from excitations over a frequency rage. A separate cooling systems through the center of the load shaft assists on the thermal management of the test bearing.

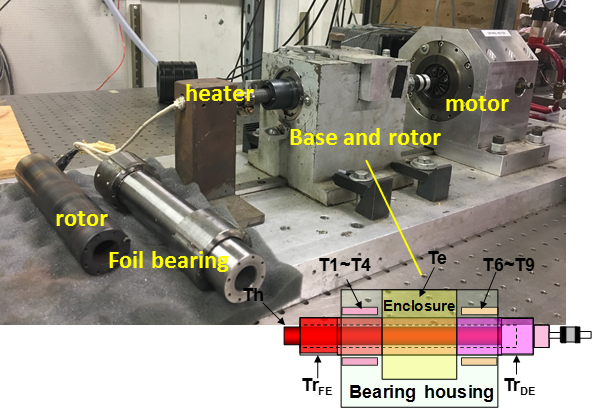

Test rig for evaluation of radial gas foil bearings operating at high temperature

Built with funds from NASA Glenn RC, the facility allows the evaluation of radial foil bearings operating at high temperature (300C). A 10 kW motor drives a rotor supported on gas foil bearings, and an electric cartridge heater increases the temperature of the hollow test rotor.

Measurements include rotor displacements using optical and infrared sensors and temperatures in the bearing cartridges. The rotor imbalance response to 50 krpm reveals the test system response, linear and nonlinear, with a parameter estimation to deliver the bearings’ effective stiffness and damping coefficients.

Tests conducted to evaluate survivability of high temperature coatings for foil bearings as well as shimmed foil bearings for MTM.

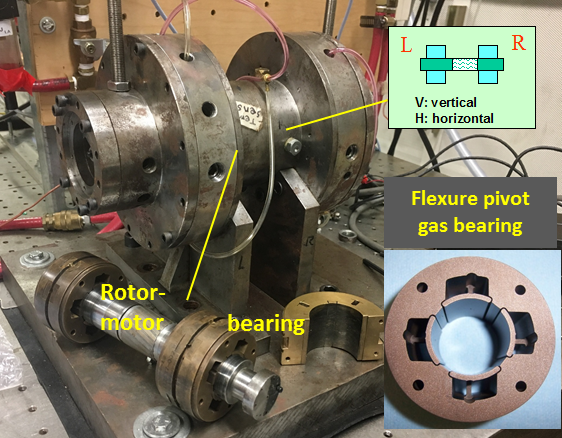

Test rig for dynamic response of rotor-motor supported on gas bearings

Built with NSF funds, the facility quantifies the response of gas bearings, flexure pivot type and porous type. An AC high frequency motor integral to the rotor with speed of 100 krpm. A pair of bearings support the test rotor (29 mm OD) to conduct tests recording the imbalance response due to a number of external excitations including road conditions (intermittent impacts) as well as base support (IC engine excitations) at low frequencies.

Test rig for static and dynamic performance of lubricated high speed bearings and seals

State of the art industrial facility with years of service to the turbomachinery industry. Sponsors (users) include various compressor manufacturers and bearing / seal makers.

Air turbine (50 kW) drives a rigid rotor supported on ball bearings. Test bearing/seal element flexibly supported at rotor middle span and connected to two shakers with maximum dynamic load of 1,000 lbf @ 320 Hz and a hydraulic static loader with maximum load of 10,000 lbf (specific load=350 psi). Rotor top surface speed is 80 m/s at 16 krpm. Instrumentation includes an in-line torquemeter, sensors for rotor displacement, and bearing accelerations and loads, and flowmeters. Bearings instrumented with up to 40 thermocouples. Operation of test rig automated with various control systems.

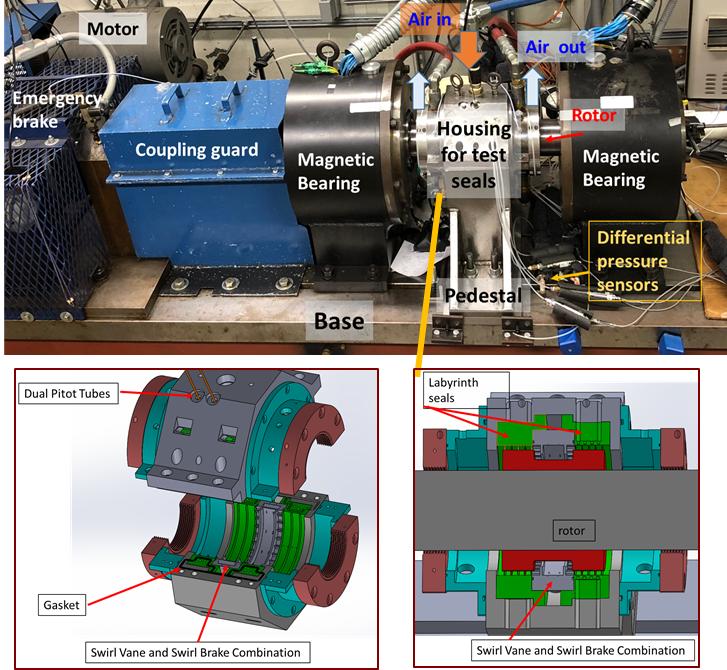

Test rig for static and dynamic performance of gas seals for advanced turbomachinery

Test rig to measure the performance of gas labyrinth seals for steam turbines and compressors.

A variable frequency drive motor turns a heavy shaft (250 lbf) that is supported on magnetic bearings. These bearings also serve to excite dynamically the rotor to whirl inside the seal test section. The housing and tests seals are split in two for easy assembly of interlocking labyrinth seals. The rig architecture takes advantage of additive manufacturing to produce inlet swirl vanes, swirl brakes and exit labyrinth seals. The rotor 150 mm in diameter at the seal section spins to a top speed of 10 krpm (surface speed of 80 m/s). Pressurized air to 300 psi and a controlled exit pressure determine the test conditions for measurement of seal leakage and pressure cavities, static and dynamic. Sponsors include steam turbine manufactures.

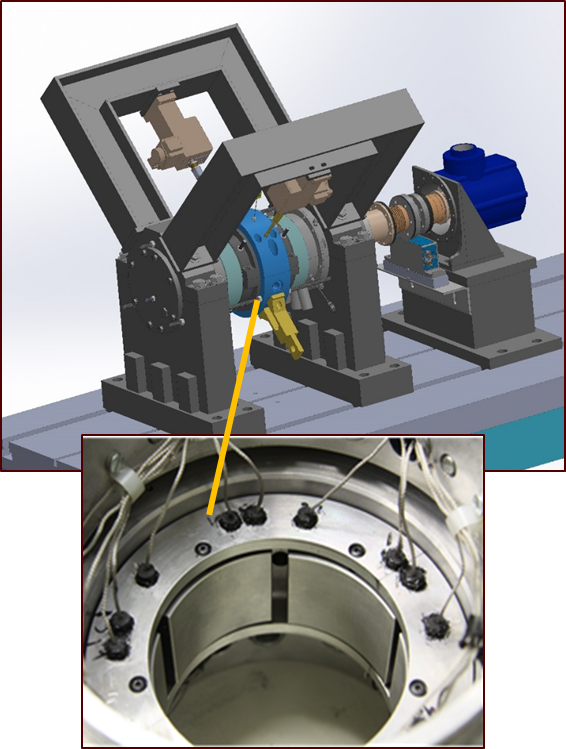

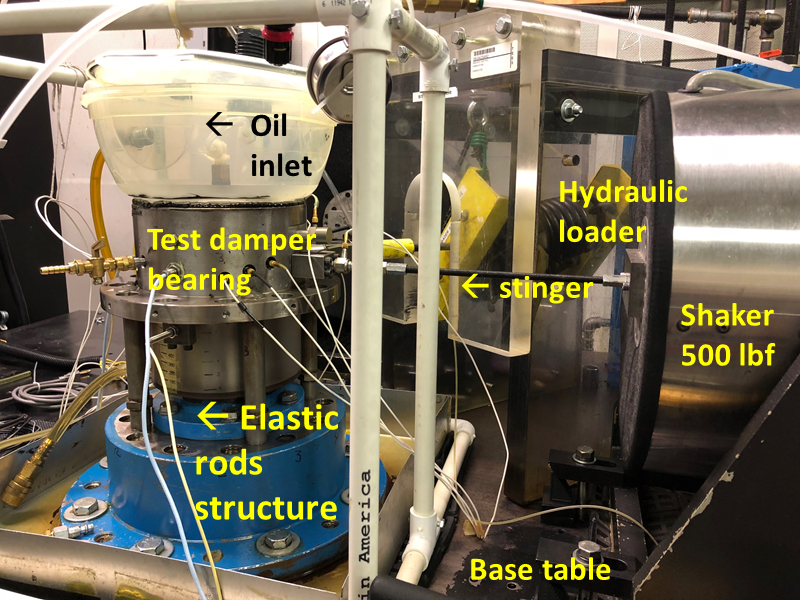

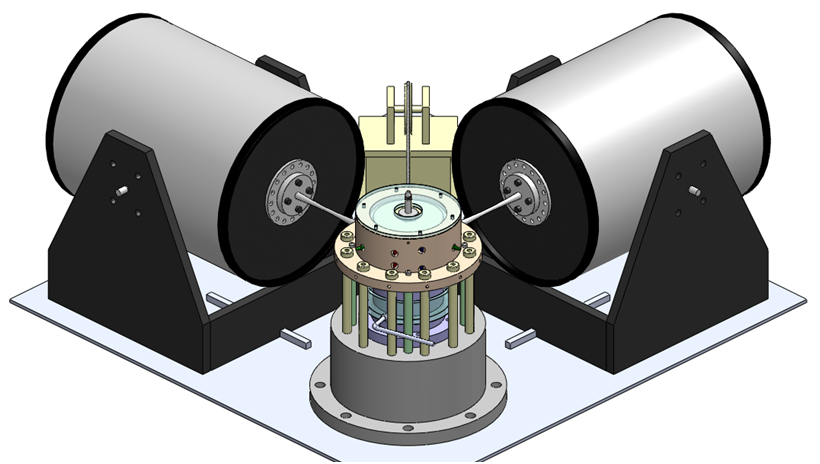

Test rig for dynamic performance of advanced squeeze film dampers for aircraft engines

Test rig to measure the dynamic forced performance of advanced squeeze film dampers used in aircraft engines, commercial and military. A major jet engine manufacturer funded the test program during ten years to produce ultra-short dampers with unsurpassed energy dissipation characteristics. This research facility is top in the world.

The test rig comprises a massive bearing cartridge (BC) supported on four elastic rods that provide a centering stiffness. The journal is solid and affixed to a heavy table. Two orthogonally positioned shakers and stingers connect to the BC and deliver excitation forces (max. 500 lbf). Engineered squeeze film damper sections are tested under a myriad of operating conditions. Measurements include film dynamic pressures, and applied forces and displacements for identification of damping and inertia force coefficients over large frequency ranges (to 200 Hz).

The facility continues to produce test results for high frequency operation with natural air ingestion that degrades the performance of dampers and also while operating under severe maneuver loads and high altitude conditions.

Other test rigs

- High temperature brush seals (leakage)

- Water thrust hydrostatic and radial bearings for turbopumps (rotordynamic response)

- Carbon-graphite gas bearings – characterization of rotordynamic response

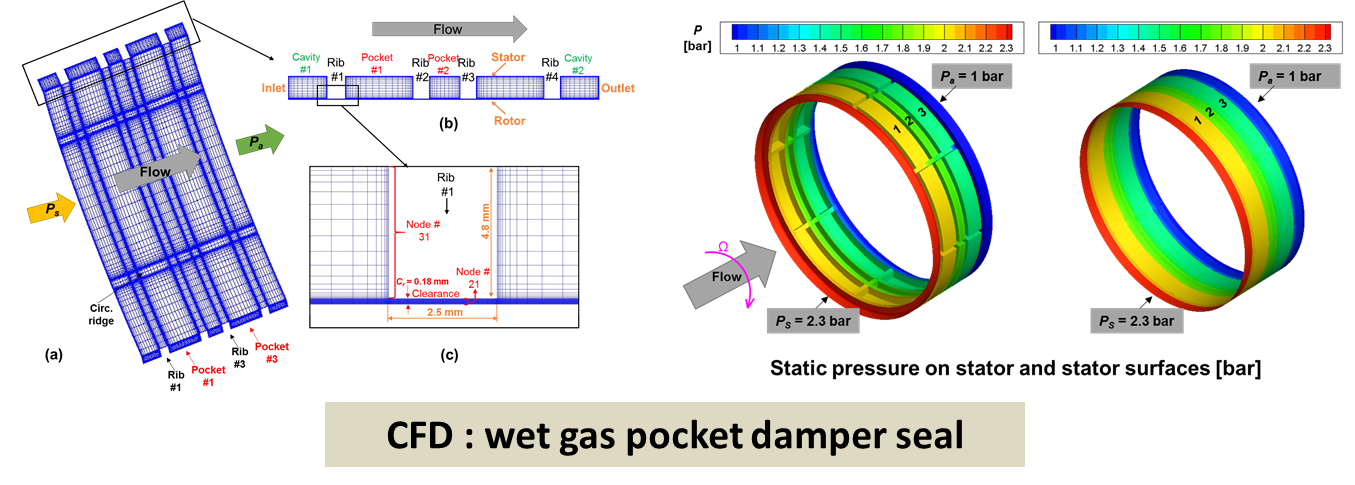

- Test rig for evaluation of gas/wet seals for the subsea industry

Computational Facilities

- High temperature brush seals (leakage)

- Water thrust hydrostatic and radial bearings for turbopumps (rotordynamic response)

- Carbon-graphite gas bearings – characterization of rotordynamic response

- Test rig for evaluation of gas/wet seals for the subsea industry